Expert insights

Technology spotlight: how NMIS is using cold spray to unlock smarter, more sustainable repair solutions

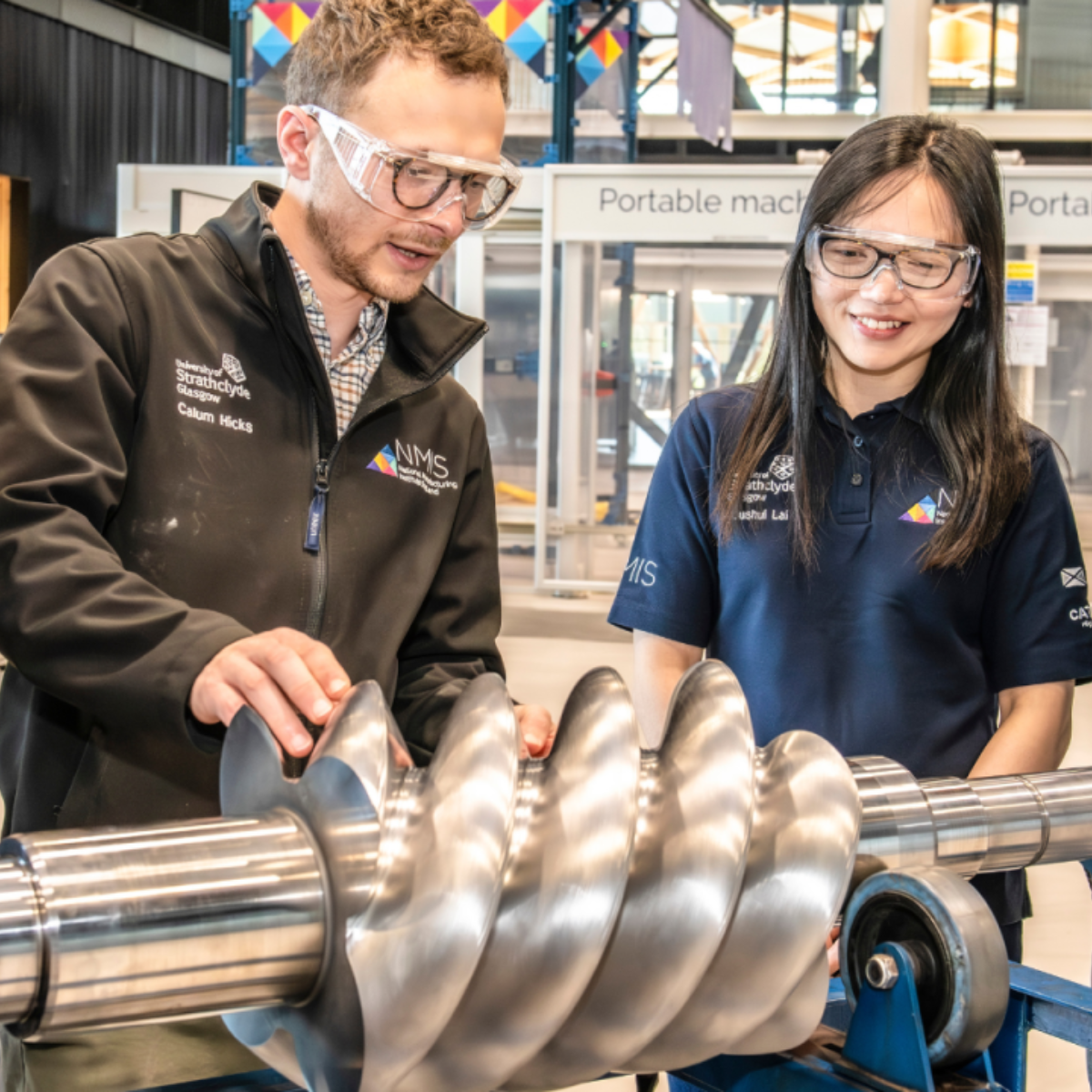

In our latest Technology Spotlight, we explore how cold spray is helping tackle some of manufacturing’s biggest sustainability challenges. As industries move away from hazardous, energy-intensive legacy processes, cold spray is emerging as a high-performance alternative for repair, refurbishment, and remanufacture.

This work is helping unlock cold spray’s potential as a mainstream tool for circular manufacturing—one that reduces reliance on raw materials and keeps products in service for longer.

Read the full article here: Technology Spotlight – Cold Spray at NMIS