In a recent feature for The Manufacturer, we discuss how Digital Product Passports (DPPs) are set to play a vital role in helping manufacturers shift towards a circular economy. With upcoming EU regulations, DPPs will be essential for compliance while unlocking opportunities to extend product lifecycles, reduce waste, and create new business models.

Key Insights:

-

The shift to a circular economy offers major opportunities to cut waste and extend product lifecycles.

-

Remanufacturing adds more value than recycling by restoring components to original or better quality.

-

From 2027, certain products sold in the EU must have Digital Product Passports (DPPs) with data on materials, processes, and carbon footprint.

-

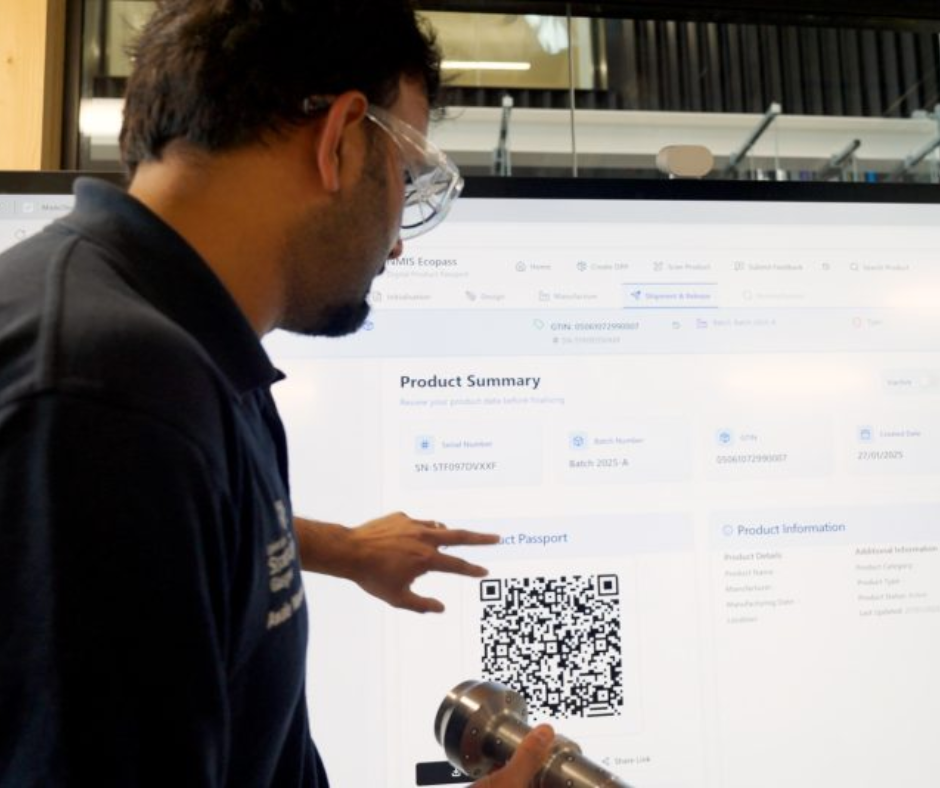

NMIS’s ReMake programme is developing tailored DPPs to streamline remanufacturing and support compliance.

-

DPPs enable new business models, reduce reliance on raw materials, and unlock revenue opportunities.

-

Remanufacturing is currently less than 2% of global material flows, highlighting massive growth potential.

Through its ReMake programme, NMIS is developing DPP solutions that give manufacturers the data needed to optimise remanufacturing and keep products in circulation for longer.